the Chartreuse WORKSHOP

The history of Ultime Sport

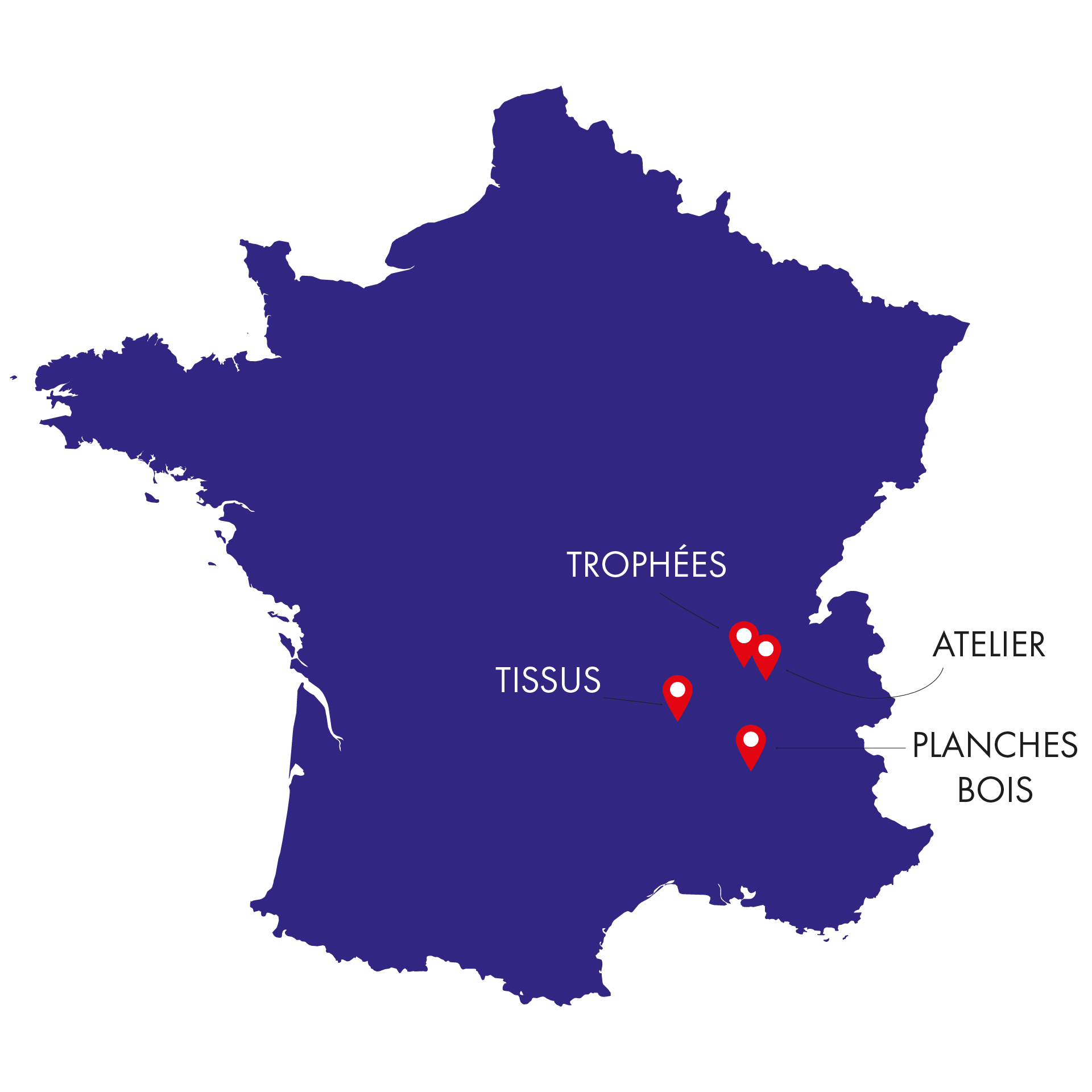

Created in 2016 in Saint-Chef in Isère, ULTIME SPORT moved to Saint-Pierre-de-Chartreuse at the beginning of 2020 in order to support its structuring and development. This change of scale has made it possible to regroup the design, the manufacture and the customization within the same place.

The company now has 20 employees and has a workshop and offices of 300 m2. This site centralizes all the know-how necessary for the creation of sports awards and tailor-made event textiles.

Located in the heart of the Chartreuse, Ultime Sport is part of a territory naturally oriented towards running, trail running and outdoor sports. An environment in line with the identity of the company and the events it accompanies in France.

THE MANUFACTURING

Made in France

Manufacturing occupies a central place in the organization of Ultime Sport. A significant part of the productions is carried out in France, directly within the Saint-Pierre-de-Chartreuse workshop, with particular attention paid to the quality, sustainability and consistency of the projects.

This choice makes it possible to offer personalized products with a strong identity, while ensuring better control of deadlines and finishes. Some ranges benefit from the Origine France Garantie® certification, attesting to compliance with the origin and processing criteria on French territory.

Our machine park

The workshop is equipped with a complete machine park to meet a wide variety of projects. It includes high-precision CO₂ laser machines, UV printing equipment, a CNC milling machine for woodworking, textile cutting solutions as well as sewing and welding equipment.

This technological complementarity offers great creative freedom, both for the manufacture of wooden medals and trophies and for the realization of personalized textile products, with a high level of precision and finish.

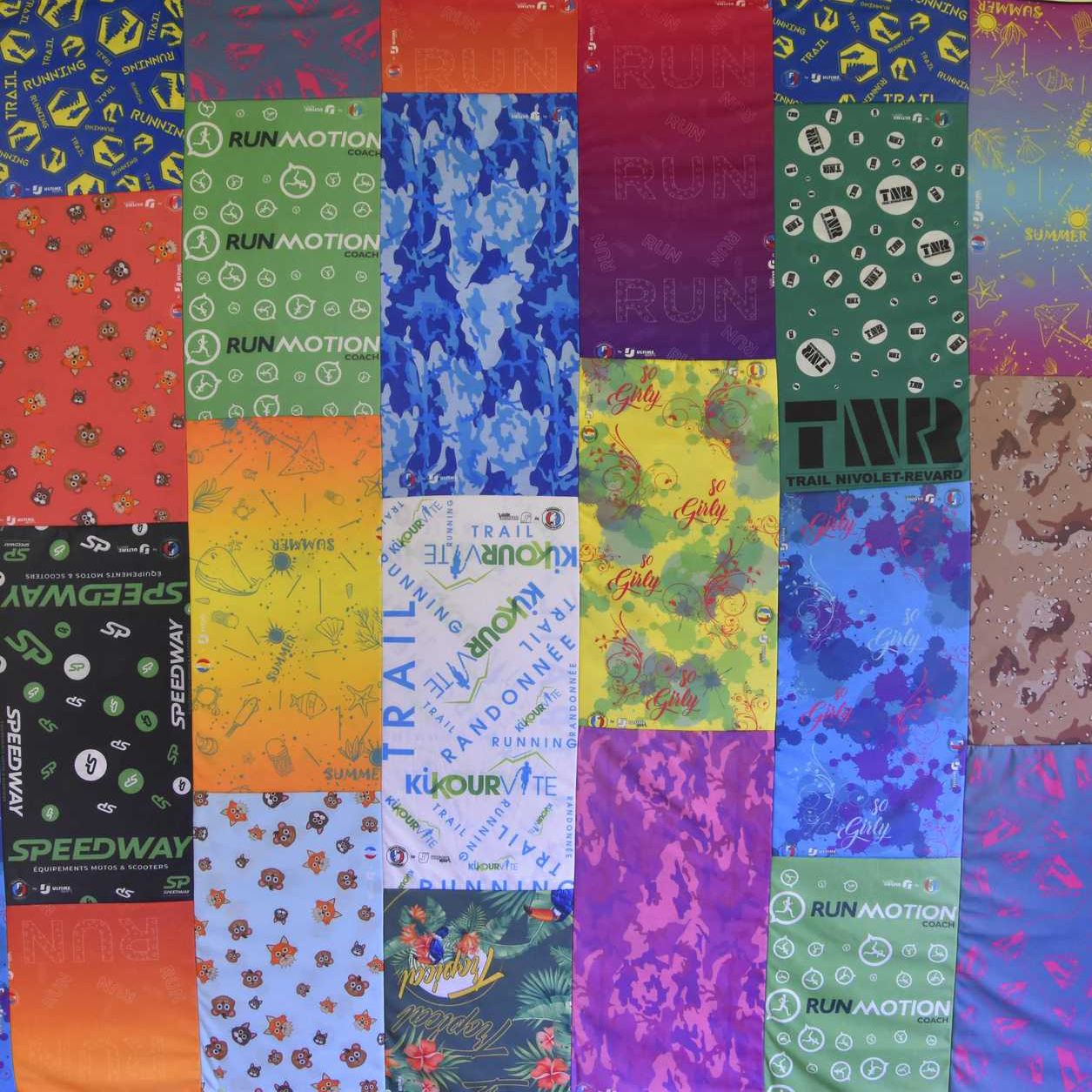

THE CONFECTION

Textile manufacturing is integrated into the workshop. After the customization and cutting phases, the products are assembled by our team, guaranteeing regularity, comfort and quality of use.

This organization makes it possible to design and assemble a wide range of technical and event textiles, adapted to the constraints of sports events and intensive use.

custom-made

At Ultime Sport, each project is the subject of tailor-made support. From the analysis of the event to the graphic creation, we design personalized solutions in close collaboration with the organizers, in order to faithfully translate the identity and values of each race.

The in-house mastery of the manufacturing stages allows us to adapt shapes, materials and finishes, and to give life to unique products and textiles, designed to fully integrate into the overall project of the event.